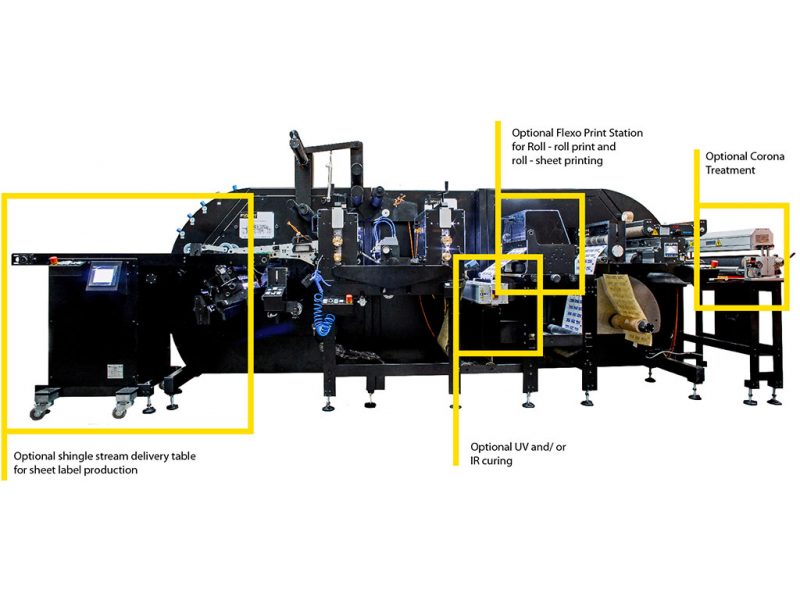

Flexor Hybrid Machine: Roll – Roll or Roll – Sheet Production Made Easy

The Flexor IQ Series is made for customers who need to manufacture Roll Labels and Sheet Labels but do not want to invest in two machines. The solution is amazingly simple yet versatile! The FLEXOR offers you everything you need to make high quality labels and at the same time be as flexible as your customers demand.

Product features:

Specifications

| Specification | 280 | 380 | 440 |

|---|---|---|---|

| Max. Web Width | 280 mm 11.02 in | 380 mm 14.96 in | 440 mm 17.32 in |

| Max. Machine Speed | 220 mpm 721.78 fpm | 220 mpm 721.78 fpm | 220 mpm 721.78 fpm |

| Max. Unwind Diameter | up to 1000mm / 40inch | up to 1000mm / 40inch | up to 1000mm / 40inch |

| Max. Rewind Diameter on Single Rewinder | 550 mm 21.65 in | 550 mm 21.65 in | 550 mm 21.65 in |

| Max. Rewinder Diameter on Double Rewinder | 350 mm 13.78 in | 350 mm 13.78 in | 350 mm 13.78 in |

| Max. Rewind Diameter on Semi Turret | 350 mm 13.78 in | 350 mm 13.78 in | 350 mm 13.78 in |

| Min. Slitting Width with Shear Knives | 20 mm 0.79 in | 20 mm 0.79 in | 20 mm 0.79 in |

| Min. Slitting Width with Razor Knives | 10 mm 0.39 in | 10 mm 0.39 in | 10 mm 0.39 in |

| Max. Magnetic Cylinder Size | 20 inch / 160 Teeth | 24inch / 192 Teeth | 24inch / 192 Teeth |

| Min. Magnetic Cylinder Size | 8inch / 64 Teeth | 10inch / 80 Teeth | 12inch / 96 Teeth |

| Die Cutting to Register: +/- 0.2mm | max. 150m/min | max. 150m/min | up to 150m/min |

| Size L x D x H | 4550x1300x1950 | 4550x1400x1950 | 4550x1500x1950 |