Produce sheets of basically any size without changing any tools

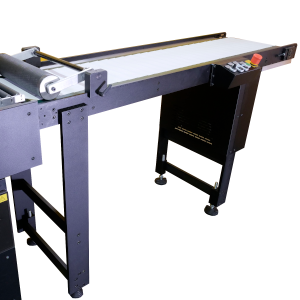

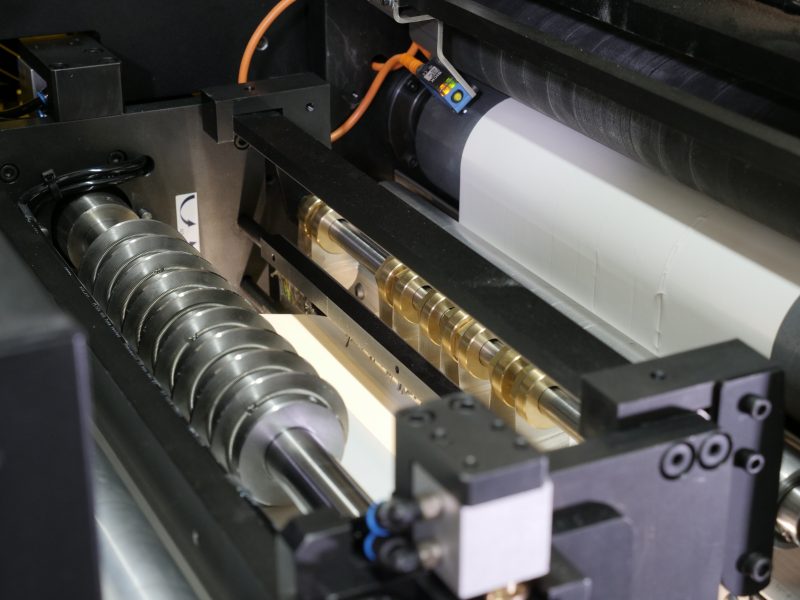

The sheeter is available for a web width of 330mm. The sheets are made using a full rotary system. By reading the print mark the sheeter adjusts itself to the paper. Being servo driven there is no waste and already the first sheet is cut correctly. It works fully offline and can be easily and quickly changed from one job to another.

Product features:

Specifications

| Specification | 330 |

|---|---|

| Max. Web Width | 330 mm 12.99 in |

| Max. Machine Speed | 100 mpm 328.08 fpm |

| Min. Sheet Length | 70 mm 2.76 in |

| Min. Sheet Width | 25 mm 0.98 in |

| Max. Unwind Diameter | 800 |

| Max. Sheet Length | 9999 mm 393.66 in |

| Size L x D x H with table | 3915x1357x1720 |

| Size L x D x H without table | 2290x1357x1720 |