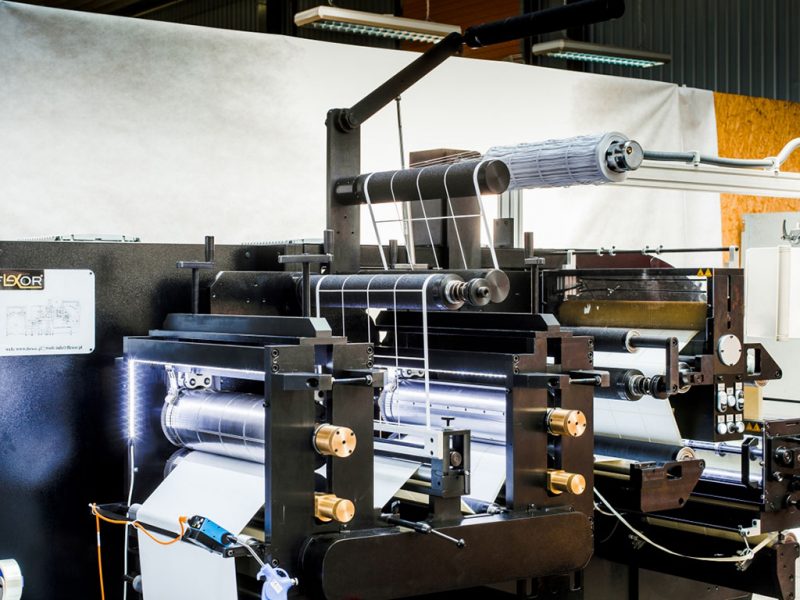

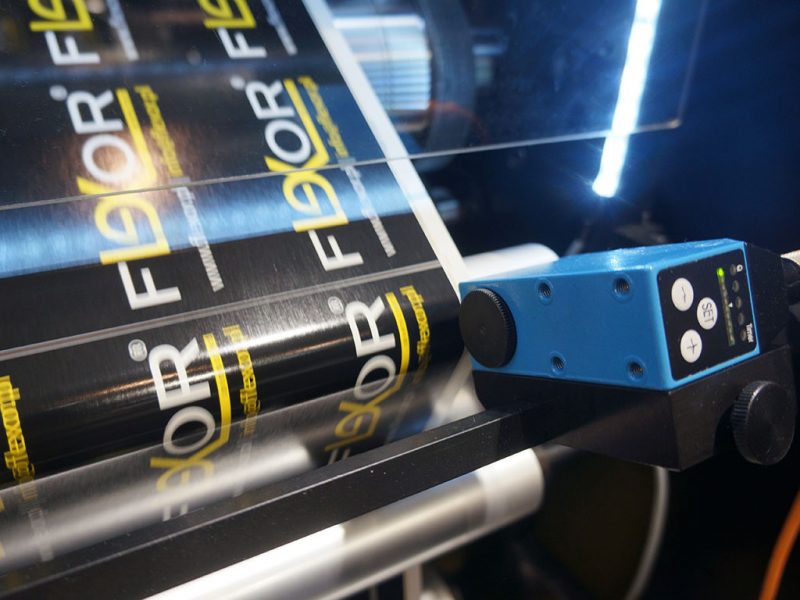

Fully Servo Die Cutter – Slitter – Rewinder for the Labels Industry

The Flexor CT Series is build for customers who demand quality, speed and efficiency. The CT Series works up to 300m/min and converts blank or pre-printed material with ease and speed. The Flexor CT Series Double Die has been designed to be able to cope with any kind of blank materials and is a highly versatile work horse. Quick, reliable, efficient means keeping the costs down and productivity up.

Product features:

Specifications

| Specification | 280 | 380 | 440 | 520 |

|---|---|---|---|---|

| Max. Web Width | 280 mm 11.02 in | 380 mm 14.96 in | 440 mm 17.32 in | 520 mm 20.47 in |

| Max. Machine Speed | 300 mpm 984.24 fpm | 300 mpm 984.24 fpm | 300 mpm 984.24 fpm | 300 mpm 984.24 fpm |

| Max. Unwind Diameter | up to 1000mm / 40inch | up to 1000mm / 40inch | up to 1000mm / 40inch | 1000mm / 40inch |

| Max. Rewind Diameter on Single Rewinder | 550 mm 21.65 in | 550 mm 21.65 in | 550 mm 21.65 in | 450 mm 17.72 in |

| Max. Rewinder Diameter on Double Rewinder | 350 mm 13.78 in | 350 mm 13.78 in | 350 mm 13.78 in | 350 mm 13.78 in |

| Max. Rewind Diameter on Semi Turret | 350 mm 13.78 in | 350 mm 13.78 in | 350 mm 13.78 in | 0 mm 0.00 in |

| Min. Slitting Width with Shear Knives | 20 mm 0.79 in | 20 mm 0.79 in | 20 mm 0.79 in | 20 mm 0.79 in |

| Min. Slitting Width with Razor Knives | 10 mm 0.39 in | 10 mm 0.39 in | 10 mm 0.39 in | 10 mm 0.39 in |

| Max. Magnetic Cylinder Size | 20 inch / 160 Teeth | 24inch / 192 Teeth | 24inch / 192 Teeth | 28 inch / 224 Teeth |

| Min. Magnetic Cylinder Size | 8inch / 64 Teeth | 10inch / 80 Teeth | 12inch / 96 Teeth | 14 inch / 112 Teeth |

| Die Cutting to Register: +/- 0.2mm | max. 150m/min | max. 150m/min | up to 150m/min | up to 150m/min |

| Size L x D x H | 2350x1300x1950 | 2350x1400x1950 | 2380x1500x1950 | 3500x1700x1500 |