Fully Servo 100% Inspection – Slitter – Rewinder for the Labels Industry

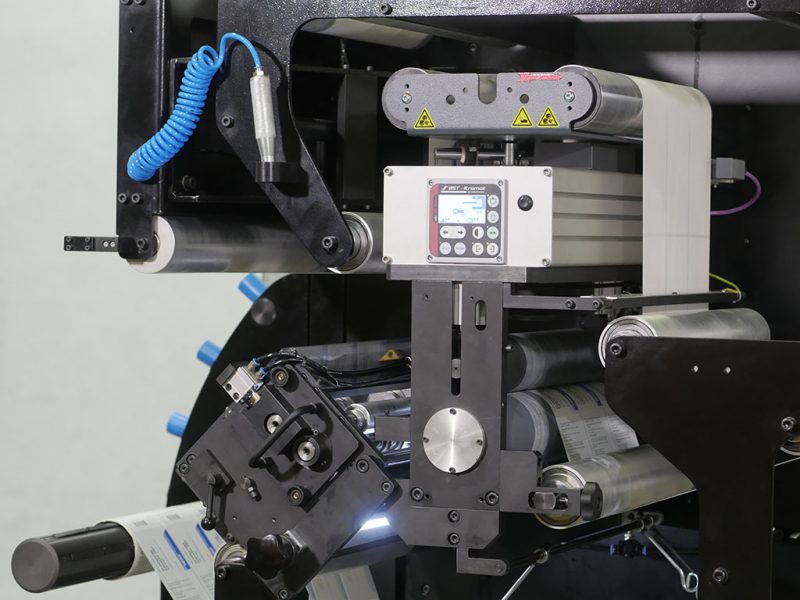

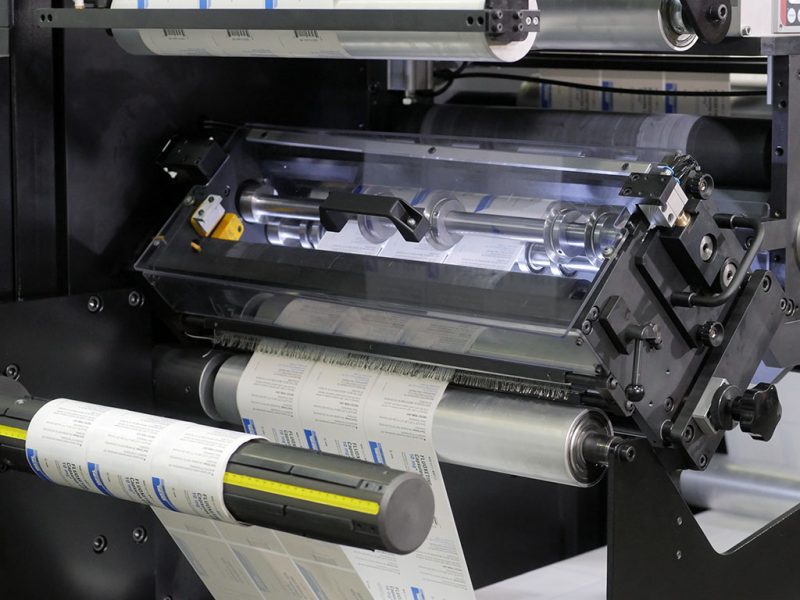

The IS Series is the ideal machine for 100% label stock inspection. It features an integrated vision camera system from one of our partners, two webguiding devices, a splice table, waste rewinder, shear and razor cutting system. This is a highly productive machine with speeds of up to 250m/min for efficient and effective label production where 100% inspection is required. The IS Series is mostly used in pharma and cosmetic label production.

Product features:

Specifications

| Specification | 280 | 380 | 440 |

|---|---|---|---|

| Max. Web Width | 280 mm 11.02 in | 380 mm 14.96 in | 440 mm 17.32 in |

| Max. Unwind Diameter | 800 | 800 | 800 |

| Max. Rewind Diameter on Single Rewinder | 550 mm 21.65 in | 550 mm 21.65 in | 550 mm 21.65 in |

| Max. Rewinder Diameter on Double Rewinder | 350 mm 13.78 in | 350 mm 13.78 in | 350 mm 13.78 in |

| Max. Rewind Diameter on Semi Turret | 350 mm 13.78 in | 350 mm 13.78 in | 350 mm 13.78 in |

| Max. Machine Speed | 250 mpm 820.20 fpm | 250 mpm 820.20 fpm | 250 mpm 820.20 fpm |

| Min. Slitting Width with Shear Knives | 20 mm 0.79 in | 20 mm 0.79 in | 20 mm 0.79 in |

| Size L x D x H | 2700x1250x1850 | 2700x1300x1850 | 2700x1400x1850 |