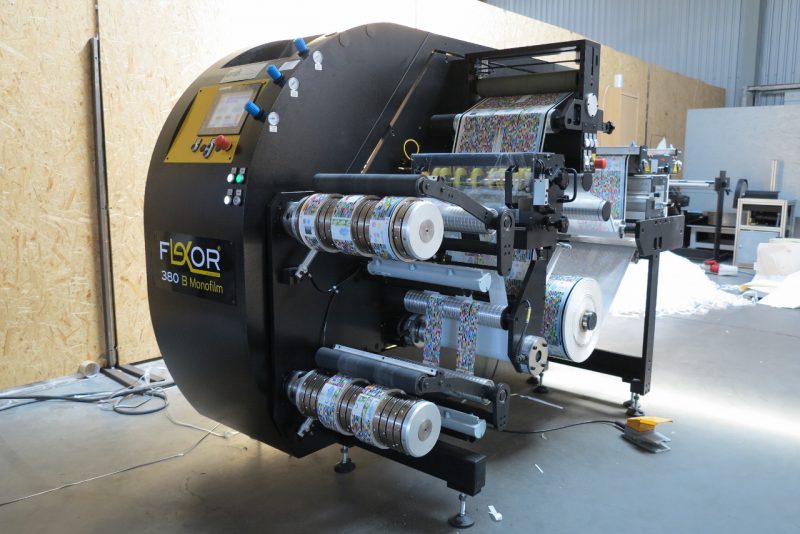

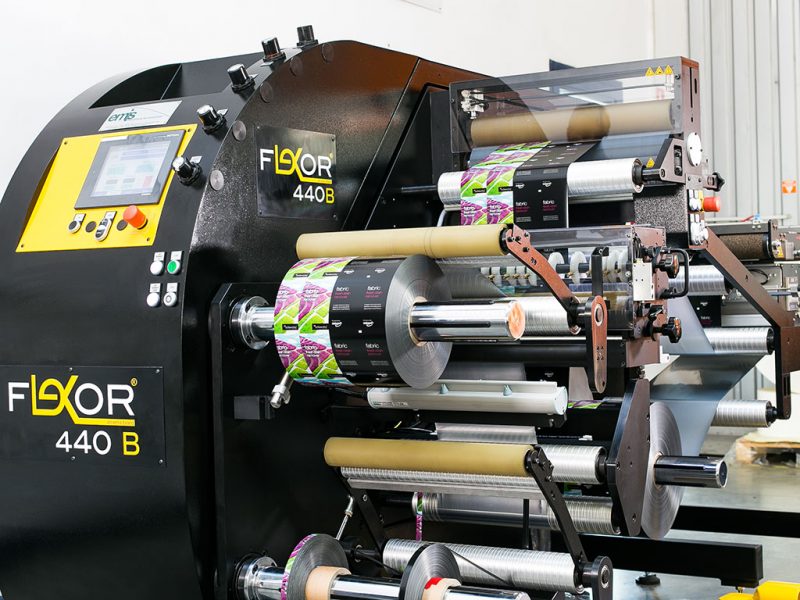

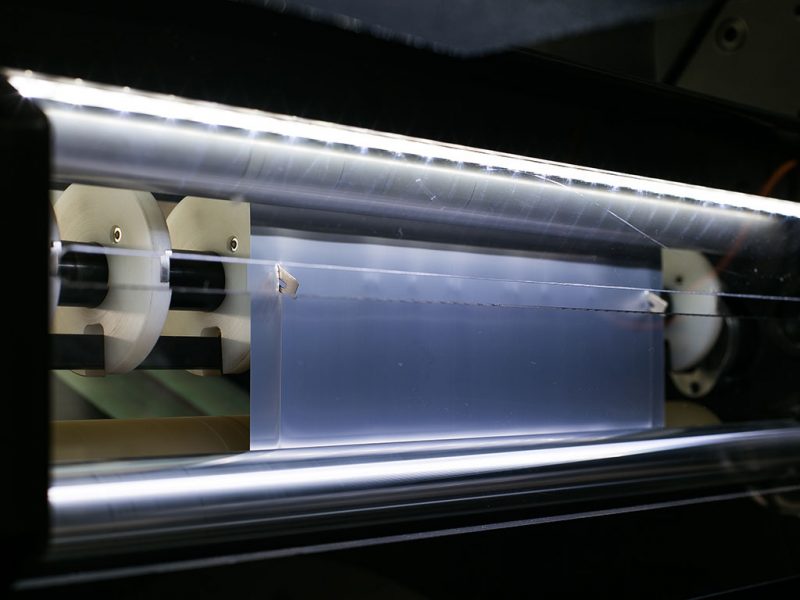

Fully Servo Inspection – Slitter – Rewinder for the Labels Industry

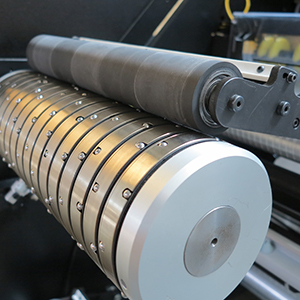

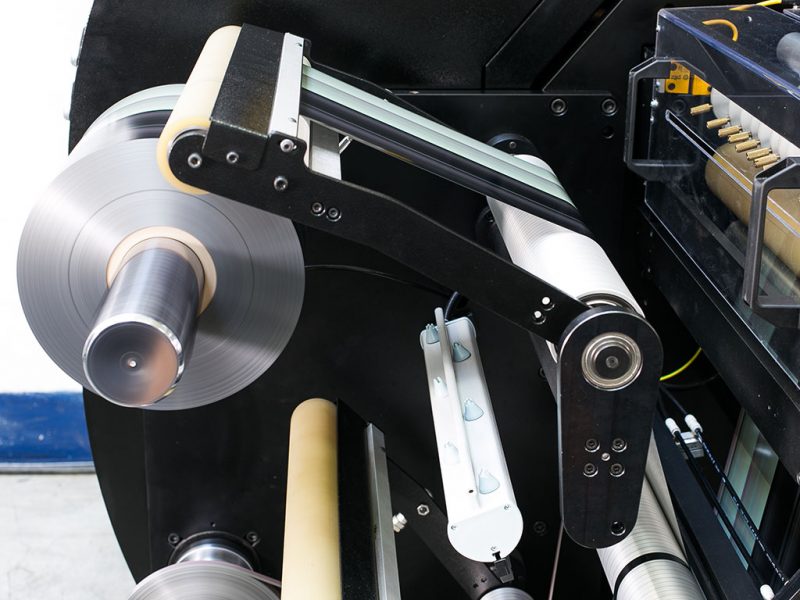

The Flexor BC Series is build for customers who demand quality, speed and efficiency. The BC Series works up to 300m/min and converts pre-printed material, films, monofilms and unsupported labelstock with ease and speed. The Flexor BC Monofilm has been designed to be able to cope with materials down to 10um and is a highly versatile work horse.

Product features:

Specifications

| Specification | 280 | 380 | 440 | 520 |

|---|---|---|---|---|

| Max. Web Width | 280 mm 11.02 in | 380 mm 14.96 in | 440 mm 17.32 in | 520 mm 20.47 in |

| Max. Unwind Diameter | 900 | 900 | 900 | 1000 |

| Max. Rewind Diameter on Single Rewinder | 500 mm 19.69 in | 500 mm 19.69 in | 500 mm 19.69 in | 500 mm 19.69 in |

| Max. Rewinder Diameter on Double Rewinder | 500 mm 19.69 in | 500 mm 19.69 in | 500 mm 19.69 in | 500 mm 19.69 in |

| Max. Machine Speed | 300 mpm 984.24 fpm | 300 mpm 984.24 fpm | 300 mpm 984.24 fpm | 300 mpm 984.24 fpm |

| Min. Slitting Width with Shear Knives | 20 mm 0.79 in | 20 mm 0.79 in | 20 mm 0.79 in | 20 mm 0.79 in |

| Size L x D x H | 2100x1300x1500 | 2100x1400x1500 | 2100x1500x1500 | 3500x1700x1500 |